Internal Model Control

for

DC Motor

Using DSP Platform

Senior Project Proposal

Advisor: Dr. Dempsey

By: Marcus

Fair

December 13, 2007

I Summary

II Problem description

III Goals

IV Technical Specs

A. Parts list

B.

Functional requirements and Specs

V Subsystem breakdown

A.

eZdsp F2812 board

B. Pittman motor

C. H-bridge

VI Preliminary work from demos

A.

PWM demo

B.

Motor velocity control demo

VII Spring Schedule

VIII Bibliography

Summary

The goal of this project is to design, build,

and test an IMC (Internal Model Control) controller that implements neural

networks to control a Pittman GM9236C534-R2 DC motor. The project will consist

of a 32-bit TMS320F2812 digital signal

processor (DSP) that will be able to read the Simulink code using the Code

Composer Studio software. The

design for the IMC controller will be built in the Simulink software. The input

to the system will be a graphical user interface (GUI) built in the Matlab

environment, where the user will be able to enter the parameters to control the

DC motor.

Problem Description

The project involves

controlling a Pittman DC motor using a 32-bit TMS320F2812 digital signal

processor (DSP) located on the ezdsp F2812 board. This is based on the senior

mini-project where an 8051 micro-controller was used to control a Pittman DC

motor using assembly language programming. However, the DSP board will play the

role of the E-Mac kit. This project will be coded in Matlab and Simulink, which

will be automatically converted to an assembly language in order to communicate

with the DSP board. Since there will be no assembly language coding in this

project more focus and energy can be put into the control theory aspects of the

design. The overall block diagram is still based on the senior mini-project so

the plant is still the Pittman DC motor. The rotary encoder in the block

diagram will still have the same gain value from the mini-project design. The

RPM calculations that convert pulses to RPM will also have the same value since

this was based off of the same DC motor values such as gear ratio. Even though

the board will communicate with both the Matlab and Simulink environment, the

code can also be written in C-code. The 32-bit DSP processor will allow many

more algorithms such as Internal Model Control and neural network control to be

investigated. The final controller will be Internal Model Control (IMC) (an

advanced controller that can be used to minimize the effects of external

disturbances). First the feed-forward controller will be implemented to test

the experimental values of the feed-forward loop. Then the IMC (internal Model

control) design will be implemented and the results will be compared to

feed-forward controller results.

Goals

1) Learn the inputs, outputs and all of the

features of the TMS320F2812

DSP and become more familiar with the hardware.

2) Design DSP/motor hardware interface.

3) Design software for PWM generation, velocity

calculation from rotary encoder, motor direction sensing, and bi-directional

motor control signals.

4) Design closed-loop controllers for velocity

control: Single-loop proportional, proportional plus derivative plus integral

(PID), and feed-forward control test system with and without external load.

5) Design and implement IMC architecture using

neural networks on the physical system.

6) Compare conventional controller results with the IMC method.

7) Design Simulink/MATLAB

graphical user interface (GUI) for controller parameter modification.

8)

Determine the limitations of the Simulink/TMS320F2812 DSP

interface in terms of real-time execution and program memory.

Equipment List

ezdsp F2812 board

Pittman

GM9236C534-R2 DC

LMD18200 H-Bridge

SN74LVC4245A 3.3-V to 5-V shifter

Tektronix

Oscilloscope

Agilent

DC power supply

Functional

Requirements and Performance

Specifications

·

Motor speed will reach up to 834 RPM

·

Motor acceleration will increase by 98 RPM per millisecond

·

System will use a 30 VDC power supply

·

The PWM timing will be a fixed period 1 khz waveform with variable

duty cycle in increments < 0.2%

·

Motor velocity display accuracy will be within + or - 10 RPM

(battery voltage 0 to 30v)

·

Optimum gains for proportional and integral controllers will be

determined based on supply variation and external load

·

Product temperature will be from 0 to 40 degrees C

·

Rise time will be 20 ms or less

·

Overshoot will be equal to or less than 5%

·

Steady state error will be less than or equal to 5 RPM

Subsystem

Breakdown

eZdsp F2812 Board

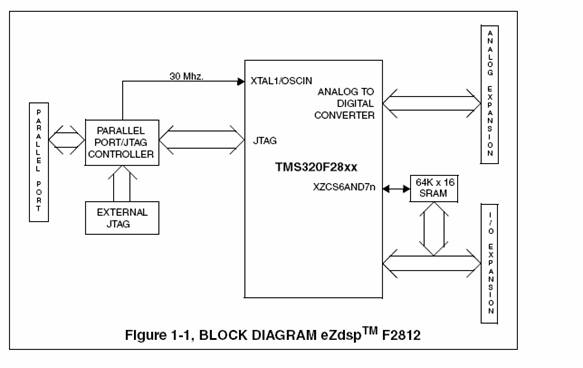

Figure 1 shows a high-level

diagram of the eZdsp F2812

board. The input will be through a graphical user interface in Simulink that

will convert the Matlab/Simulink code using Code Composer Studio 3.0. This

software sends the code to the DSP board through the parallel port. Code

Composer is necessary to convert the code into a form that can be read by the

DSP processor. The DSP chip is then run off of the code to produce a PWM signal

that runs the Pittman Motor.

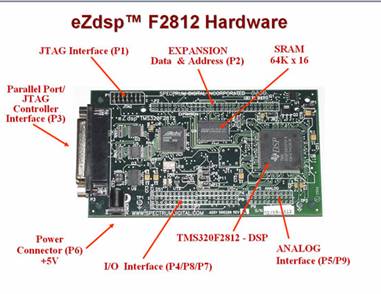

Figure 1 “Block Diagram of

eZdsp F2812 connections” eZdsp F2812 Specs Figure 2

“ezdsp F2812 board layout”

eZdsp F2812 Specs Figure 2

“ezdsp F2812 board layout”

|

Generation |

TMS320F281x

Controllers |

|

CPU |

1 C28x |

|

Peak MMACS |

150 |

|

Frequency(MHz) |

150 |

|

RAM |

36 KB |

|

OTP ROM |

2 KB |

|

Flash |

256 KB |

|

EMIF |

1

16-Bit |

|

PWM |

16-Ch |

|

CAP/QEP |

6/2 |

|

ADC |

1 16-Ch

12-Bit |

|

ADC Conversion Time |

80 ns |

|

McBSP |

1 |

|

UART |

2 SCI |

|

SPI |

1 |

|

CAN |

1 |

|

Timers |

3 32-Bit GP,1

WD |

|

GPIO |

56 |

|

Core Supply (Volts) |

1.9 V |

|

IO Supply (Volts) |

3.3 V |

|

Operating

Temperature Range (°C) |

-40 to 85,-40 to

125 |

H-bridge and External Hardware

Figure 3 shows the single-loop controller diagram that was used for the senior mini-project. The H-bridge will be the amplifier used to step up the voltage of the PWM signal. Other external hardware such as protection circuitry will be included in the system but is yet to be determined yet.

Figure 3 “Single-loop Control

of DC motor using DSP board”

LMD18200 H-Bridge Specs

|

Delivers up to 3A continuous

output |

|

Operates at supply voltages up to

55V |

|

Low RDS(ON)

typically 0.3W per switch |

|

TTL and CMOS compatible inputs |

|

No “shoot-through” current |

|

Thermal warning flag output at 145°C |

|

Thermal shutdown (outputs off) at 170°C |

|

Internal clamp diodes |

|

Shorted load protection |

|

Internal charge pump with external bootstrap

capability |

|

Internal clamp diodes |

|

Shorter load protection |

|

Internal charge pump with external

bootstrap capability |

Pittman DC motor

The Pittman DC motor block

diagram in Figure 4 consists of a transfer function that corresponds to the

electrical side and another transfer function that corresponds to the

mechanical side. The transfers function for the electrical side and mechanical side

were calculated in the Electronic Product Design lab. The incoming signal to

the first transfer function represents a difference of the control voltage and

the feedback voltage while the output to this transfer function represents the

armature current. The current is multiplied by the torque constant gain (kt)

whose output is converted to torque. The torque is then multiplied by the

transfer function that represents the mechanical side of the motor such as

stiffness, friction, and inertia. The final output is rotational velocity. The

voltage constant gain (kv) in the feedback loop converts the rotational

velocity back into a voltage.

Figure 4 “Block Diagram of

Pittman Motor”

Motor

specs

|

Part # |

GM9236C534-R2 |

|

Gear ratio |

5:9:1 |

|

No-load

at 30V |

800 RPM, current 100

ma |

Encoder Specs

|

Input Voltage |

5V |

|

Resolution |

512 ppr (before gear reduction |

|

|

|

IMC Controller

Figure

5 shows the IMC controller used in a single feedback loop configuration. The

IMC loop consists of the plant Gp and the transfer function Nc. Nc computes the

difference between the outputs of the process and of the IMC. This difference

represents the effect of disturbances and of a mismatch of the model. The IMC

architectures have been shown to have good robustness properties against

disturbances.

Figure 5 “Block Diagram of IMC for Disturbance Rejection”

Preliminary

Lab Work

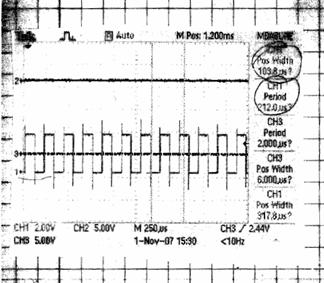

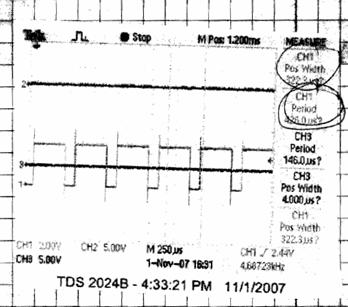

The

PWM demo utilizes the PWM 1 and PWM2 pins from the DSP board. In this demo, the

oscilloscope was connected to the PWM1 pin. In this demo, the period of the

signals were changing between 16000 and 32000 clock cycles every 1.6s. The duty

cycle of the pulse waveform is determined by the ratio of the pulse width and

the pulse period. The duty cycle of the PWM signal was changing between 50% and

75% as seen in figures 5 and 6.

Figure

6 “PWM signal at 50% duty cycle”

Figure

7 “PWM signal at 75% duty cycle

A

second demo was also ran in Matlab where the DC motor and H-bridge were

connected to the DSP board. Protection circuitry were connected between the DSP

board and the H-bridge since the DSP board could only work with 3.3v inputs and

outputs. The rotary encoder of the dc motor was ran off of the 5v internal

power supply of the DSP board. The motor speed and other parameters were set in

the MATLAB GUI. The speed setting was sent to the controller code running on

the DSP via RTDX. The controller constantly adjusted the duty cycle of the PWM

waveform driving the motor to maintain the desired speed. This demo was a way

to experiment with how the hardware components of the project would connect

with the DSP board and also to experiment with the MATLAB GUI.

|

|

|

|

Spring Semester Schedule |

|||||

|

|

|

|

|

|

|

|

|

|

|

week |

|

|

|

|

|

|

|

|

|

1-4 |

|

|

Build and test single-loop

controller, Design initial Gui layout |

|

|

|

||

|

5 |

|

|

Build and test feed-forward

controller |

|

|

|

|

|

|

6-8 |

|

|

Train the neural network in

simulation and experimental |

|

|

|

||

|

9 |

|

|

Implement neural network as

feed-forward control |

|

||||

|

10 |

|

|

Implement IMC with linear model |

|

|

|

||

|

11 |

|

|

Implement IMC with neural network |

|

|

|

||

|

12 |

|

|

Design alternative neural network

method, final testing, final Gui design |

|

|

|

||

|

13-14 |

|

|

Final documenation |

|

|

|

|

|

The

first reference is a link to the website that contains the technical reference

for the DSP board. It contains the pinout diagram, input and outputs, memory

layout, and hardware and software features for the ezdsp board. The 2nd link is

a reference to the theory of IMC controllers. The 3rd link is a reference

to the datasheets for the Pittman motor and the h-bridge.

Bibliography

http://c2000.spectrumdigital.com/ezf2812/

http://lorien.ncl.ac.uk/ming/robust/imc.pdf

http://blackboard.bradley.edu/webapps/portal/frameset.jsp?tab_id=_2_1&url=%2Fwebapps%2Fblackboard%2Fexecute%2Flauncher%3Ftype%3DCourse%26id%3D_41146_1%26url%3D