Internal Model Control

for

DC

Motor

Using DSP Platform

Advisor: Dr. Dempsey

By: Marcus Fair

November 12, 2007

Problem Description

The project

involves controlling a Pittman DC motor using a 32-bit TMS320F2812 digital

signal processor (DSP) located on the ezdsp F2812 board. This is based on the

senior mini-project where an 8015 microcontroller was used to control a Pittman

DC motor using assembly language programming. However, the DSP board will play

the role of the E-Mac kit. This project will be coded in Matlab and Simulink,

which will be automatically converted to an assembly language in order to

communicate with the DSP board. Since there will be no assembly language coding

in this project more focus and energy can be put into the Control theory

aspects of the design. The overall block diagram is still based on the senior

mini-project so the plant is still the Pittman DC motor. The rotary encoder in

the block diagram will still have the same gain value from the mini-project

design. The RPM calculations that convert pulses to RPM will also have the same

value since this was based off of the same DC motor values such as gear ratio.

Even though the board will communicate with both the Matlab and Simulink

environment, the code can also be written in C-code. The 32-bit DSP processor

will allow many more algorithms such as Internal Control Model and neural

network control to be investigated. The final controller will be Internal Model

Control model (IMC) which is an advanced controller that can be used to

minimize the effects of external disturbances. The feed-forward design will

first be put together to test the experimental values of the feed-forward loop

first. Then the IMC (internal Model control) design will then be implemented

and then the results will be compared to feed-forward controller results.

Goals

1) Learn the

inputs, outputs and all of the features of the TMS320F2812 DSP

and become more familiar with the hardware.

2) Design DSP/motor hardware interface.

3) Design

software for PWM generation, velocity calculation from rotary encoder, motor

direction sensing, and bidirectional motor control signals.

4) Design

closed-loop controllers for velocity control: Single-loop proportional,

proportional plus derivative plus integral (PID), and feed-forward control test

system with and without external load.

5) Design and

implement IMC architecture using neural networks on the physical system.

6) Compare conventional controller results with the IMC method.

7)

Design Simulink/MATLAB graphical

user interface (GUI) for controller parameter modification.

8) Determine the limitations of the

Simulink/TMS320F2812 DSP interface in terms of real-time execution and program

memory.

Subsystem

Breakdown

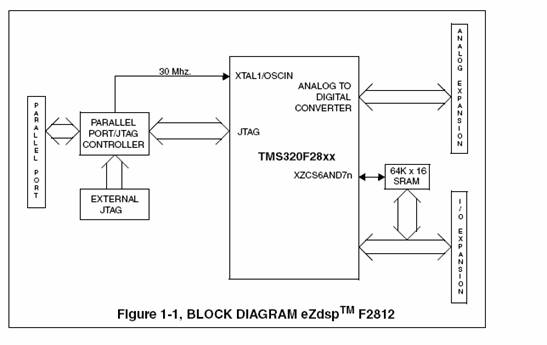

Figure 1 shows a high-level

diagram of the F2812 board. The input will be through a graphical user

interface in Simulink that will convert the Matlab/Simulink code using Code

Composer Studio 3.0. This software sends the code to the DSP board through the

parallel port. The Code composer is necessary to convert the code into a form

that can be read by the DSP processor. The DSP chip is then run off of the code

to produce a PWM signal that runs the Pittman Motor.

Fig. 1

“Block Diagram of eZdsp F2812 connections”

Figure 2 shows the single-loop controller diagram that was used for the senior mini-project.

Fig. 2 “Single-loop

Control of DC motor using DSP board”

The Pittman DC motor block

diagram in Figure 3 consists of a transfer function that corresponds to the

electrical side and another transfer function that corresponds to the

mechanical side. The incoming signal to the first transfer function represents

a difference of the control voltage and the feedback voltage while the output

to this transfer function represents the armature current. The current is

multiplied by the torque constant gain (kt) whose output is converted to

torque. The torque is then multiplied by the transfer function that represents

the mechanical side of the motor such as stiffness, friction, and inertia. The

final output is rotational velocity. The voltage constant gain (kv) in the

feedback loop converts the rotational velocity back into a voltage.

Fig. 3 “Block Diagram of

Pittman Motor”

Fig. 4 shows the internal model control used in a single

feedback loop configuration. The IMC loop which consists of the plant Gp and

the transfer function Nc computes the difference between the outputs of the

process and of the IMC. This difference represents the effect of disturbances

and of a mismatch of the model. The IM architectures have been shown to have

good robustness properties against disturbances.

Fig. 4 “Block Diagram of

IMC for Disturbance Rejection”

References

eZdspTM F2812 2003 DSP

Development Systems

http://www.spectrumdigital.com/product_info.php?&products_id=138

Reference