The following signals will be available on the D/A converter output

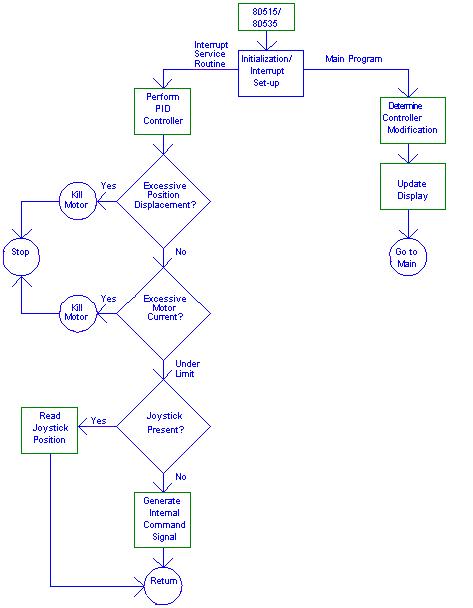

channels. The expanded control block

diagram is shown in Figure 1.

Command position - Desired robot arm position from joystick or keypad input.

Feed-forward signal - The output signal from the feed-forward compensator.

Error signal - The difference between the command signal and the filtered position signal.

PID-type controller signal

- The output signal from the PID(proportional+integral+derivative)-type

controller.

Controller Output - Signal that drives the robot arm system, connected to power amplifier.

Filtered position signal

- The filtered actual position sensor signal.

Sensor H(s)

- H(s) = 0.028 volts/degree

Filter F(s) - Low pass digital filter.

Plant Gp

- Gp = (29.8e^-0.02s)/( ( s/3.6 + 1 ) (s/3.6 + 1 ))

Dead-zone due to static friction was modeled as 20 ms time delay.

Note

that this is a type 0 system.