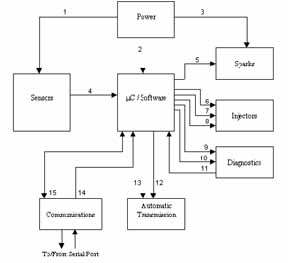

Power:

This subsystem contains all circuitry

that will regulate power to the microprocessor, sensors, and sparks subsystems.

This would include such circuits as voltage regulators, converters, line

conditioners, and oscillators.

Sensors:

This subsystem contains the physical

sensors and the interfacing to the microprocessor. Any analog to

digital converters, filters, and scaling circuitry would be contained in

this system.

uC / Software:

This subsystem contains the microprocessor,

address decoding circuitry, and program EPROM. The EPROM will contain

the code for the controller, in which a full program flow chart is shown

in Fig I. This subsystem can be looked upon as the brains of the

operation, because all the inputs and outputs will be maintained from here.

Manipulating the control outputs based on the inputs received from the

sensor subsystem attains the control of the engine.

Sparks:

The spark subsystem contains the

ignition coils. It accepts a timing input from the microprocessor

and fires the spark plugs accordingly.

Injectors:

In this subsystem, the injectors,

fuel pump, and timing/sequence circuitry are contained. The function

of the system is to control the injector sequence and duration of fuel

spray into the pre-combustion chamber. During startup, the fuel relay

pump is turned on prior to starting the engine so that the fuel line is

pressurized. This allows pre-prime of the engine prior to startup.

Diagnostics:

This subsystem is responsible to

maintain the reliability and working condition of the controller.

Two inputs, power and error detection, allow the driver to provide the

controller with immediate attention. This system also maintains the

trouble shooting routine that tests the controller to ensure working condition,

and if not, return the error code corresponding to the detected problem.

Automatic Transmission:

This system contains two power

transistors that will be used to control the up and down sequence of the

transmission. Two inputs from the microprocessor will determine when

the transmission is to shift.

Communications:

This subsystem will maintain the

link between the controller and the outside world. A serial communication

port will be used to establish a link to a PC for reading of diagnostic

codes and real-time calculations. The EPROM look-up table is also

contained in this subsystem because it can be exchanged to incorporate

other desired engine characteristic.

Key to Labels:

1) Power to

Sensor Subsystem

2) Power to

Microprocessor

3) Power to

Spark Ignition System

4) Sensor Inputs

to Microprocessor

5) Timing for

Sparks

6) Fuel Relay

Control Signal

7) Injection

timing Signal

8) Revolution

Limiting Signal

9) Power Detect

Signal

10) Error Detect

Signal

11) Diagnostic

Start Input

12) Transmission

Shift Up

13) Transmission

Shift Down

14) Lookup Table

Signal

15) Serial Port

Communication